Knitted wire gaskets in different shapes and materials

Knitted wire gaskets consist of metal wires that are knitted and can be formed to several shapes. However, the following shapes have developed to a sort of standard:

- round profiles

- round core with fin

- rectangular profiles

- double round core with fin

Standard metal wires are:

- FCS (tin plated copper clad steel)

- (alloy of nickel and copper)

- Aluminum

Various dimensions possible

Due to flexible manufacturing processes all requested dimensions can be realized. Dimensions shown just give a picture of what is possible to manufacture.

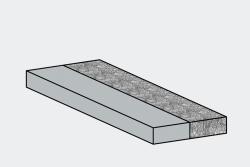

Knitted wire material can also be supplied as flat band material wiht a thickness of approximately 0,5 mm and standard widths from 6,4 to 31,1 mm.

FCS provides very good shielding attenuation also in the magnetic field.

provides very good shielding attenuation in combination with a high corrosion resistance.

Knitted wire over elastomer for higher elasticity

If the application requires higher gasket elasticity a gasket with an elastomer core should be chosen.

Those gaskets consist of an elastomer core that is knitted over with metal wire. Two layers are standard, however, it is also possible to use one layer or more layers.

Application of combi gaskets

material is mainly neoprene foam, -foam, PU-foam and silicone-foam, whereat neopren and are mostly chosen.

A protection against environmental influences, such as dust and circulating air, is given. A protection against water (spraying water etc.) is not possible. If the application requires a resistance against dropping or spraying water then a so-called combi gasket should be chosen. These gaskets consist of a non conductive elastomer with PSA backing and knitted wire gasket that is mounted alongside the edge of the elastomer. The knitted wire can be a full metal mesh gasket as well as a knitted wire over elastomer gasket.

In some cases it is necessary to use a very soft gasket. This can be realized by knitting just one layer of a very fine metal wire over a PU-foam.

As an option a non conductive PSA can be applied to the gaskets. It should only be seen as a support during the mounting of the gasket.

To prevent galvanic corrosion engineers should take notice of the electrochemical potential of the wire in combination to the metal used for the chassis, enclosure etc.

Tolerances

| width & height (mm) | < 10,0 | +/- 0,8 |

| > 10,0 | +/- 1,5 | |

| lenght (mm) | > 5,0 | +/- 2,0 |